I’ve been pretty busy lately, not a small part of which is doing some wood working. This is something I enjoy as much as photography. I get a deep pleasure taking rough lumber and making something nice and usable from it. I thought I would run through the process of going from rough lumber to a finished product. In this case a cutting board set I am doing for Lindsay. The pictures in this process are using bloodwood, from Central and South America. Videos would be a much better presentation but I’m not very adept at making them. Just getting pictures took long enough.

The process starts with milling rough cut lumber into something flat with a square edge for a cutting reference. I use rough cut lumber because it is a lot less expensive than finished boards. Rough cut means just that. It isn’t planed smooth and doesn’t have a finished edge. It usually has some warp and twist to it also. It isn’t the safest thing to cut because it can twist in the saw and move unpredictably.

Full length board showing warp.

Full length board showing warp.

Close up showing the amount of warp with the rough sides and edges.

Close up showing the amount of warp with the rough sides and edges.

The first task is to cut boards that may range from six to ten feet long into something manageable. Cross-cutting on the table saw would work, but I think using the miter saw (or chop saw) is easier and safer. The miter saw bed is short, so the boards need to be supported. The end result is a stack of boards that now need to be planed to provide flat surfaces.

Full length board on the saw. The long blue hose connects to a shop vac.

Full length board on the saw. The long blue hose connects to a shop vac.

Cutting the boards. Notice the appropriate safety gear.

Cutting the boards. Notice the appropriate safety gear.

The end result, a pile of rough finished boards ready for the next step.

The end result, a pile of rough finished boards ready for the next step.

I have to do planing with a surface, or parallel, planer. A larger shop would use a jointer for this purpose. Since I don’t have the room, or money, for a jointer, I use the planer. One can’t just run the rough boards through the planer. A parallel planer does just that, it makes the two sides of the board parallel to each other. The bottom side serves as a reference and the planer smooths the top side of the board. Without having a flat smooth reference side, any deformity like a twist or warp in the wood is transferred to the top side. You end up with a board that has smooth, twisted sides. Not very usable.

The way around this is to use a planer sled. A planer sled is simply a flat piece of material, in my case a man-made product called MDF. You place your board on the sled, and glue wedges in the gaps between the board and the sled. The wedges steady the board as you plane it, so you will get a smooth surface without any twists or warps. Sacrifice boards at the beginning and end of the boards prevent what is called planer snipe. This is where the planer cutters first gouge into the wood. The snipe ends up in the sacrifice boards, not your production boards.

Wedges glued between the board and the sled.

Sled with two wedged up boards. My sled is 1.5 inch MDF. It gets pretty heavy when loaded with a dense wood like bloodwood.

Sled with two wedged up boards. My sled is 1.5 inch MDF. It gets pretty heavy when loaded with a dense wood like bloodwood.

Once set up, the sled is run through the planer. Each pass through the planer will trim off the highest areas of the board. I typically trim something like 1/32” to 1.64” on each pass. Deeper cuts are possible, but I run right at the limit of what my circuit breakers can handle. Deeper cuts can cause the planer to draw too much current and trip a breaker. This causes a gouge in the wood where the cutters stop and a lot of swearing on my part. I don’t have a shot at heaven as long as I’m woodworking. Eventually, after a lot of passes, I have boards with one smooth flat surface.

Sled on the planer.

Sled on the planer.

Sled coming through the planer.

Sled coming through the planer.

Smoothing on successive passes.

Smoothing on successive passes.

Finished smooth boards.

Finished smooth boards.

Smooth board and rough board for comparison.

Smooth board and rough board for comparison.

The smooth flat side of the board now provides a good reference for planing the other side of the boards, without using the sled. Sacrifice boards are still required to eliminate snipe. When planing multiple boards there is a certain amount of juggling to keep a steady flow going through the planer. On this run I had three shorter boards (two feet long) and two longer boards (three feet long). Lise helped to keep the outfeed boards from falling to the floor.

Planning the second side of the boards.

Planning the second side of the boards.

Once the boards have been planed and flattened on both sides, I still need to get a straight edge perpendicular to the planed sides. This will give a reference edge for cutting the boards down to the needed size. To get a straight edge I use a jig I made. It has a straight reference side, and clamps to hold a board in place. When a board is clamped in the jig, the reference side of the jig is braced against the table saw fence, and a strip cut off the board. This process produces boards that are flat on two sides, and have clean edge, square to the board surfaces.

Board clamped into jig.

Board clamped into jig.

Running the board and jig through the table saw to produce a clean edge, square to the surface. That spinning blade is not something to be trifled with. A mistake here can make counting to five on one hand difficult if not impossible.

Running the board and jig through the table saw to produce a clean edge, square to the surface. That spinning blade is not something to be trifled with. A mistake here can make counting to five on one hand difficult if not impossible.

Finished board. Two flat parallel sides and a smooth edge square to the sides for a cutting reference.

Finished board. Two flat parallel sides and a smooth edge square to the sides for a cutting reference.

Comparison of finished board and an unprocessed board.

Comparison of finished board and an unprocessed board.

I now have the bloodwood milled. I have to repeat the process for all the wood I’m using. In this case hard maple, plus maybe some cherry, black walnut, and purple heart. After milling we get into the cutting, gluing, smoothing, routing, sanding, and finishing. Fun stuff and the subject of the next post or two.

Behind that log is a Code 4 species.

Behind that log is a Code 4 species. Lots of optics. Lise is the second person back., looking through the scope.

Lots of optics. Lise is the second person back., looking through the scope. Wilted lotus leaf.

Wilted lotus leaf.

Lise messing with me when I’m trying to take pictures of lotus leaves.

Lise messing with me when I’m trying to take pictures of lotus leaves.

Ya gotta go with what ya got.

Ya gotta go with what ya got.

Stefan, Kasey, and Ava, post baptism.

Stefan, Kasey, and Ava, post baptism. Waiting for the Mexican take-out order.

Waiting for the Mexican take-out order. All that’s missing is scrapple.

All that’s missing is scrapple. Niece Katie, and her daughter Charlee , down from the Aleutian Islands.

Niece Katie, and her daughter Charlee , down from the Aleutian Islands. Anita, in from PA, with nephew Zack, and his daughter Stella in from Chicago.

Anita, in from PA, with nephew Zack, and his daughter Stella in from Chicago.

All glued and planed.

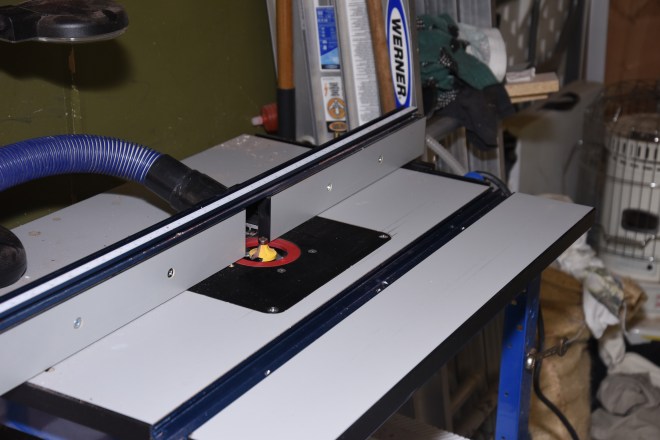

All glued and planed. Round over router bit.

Round over router bit.

Routing using a table saw crosscut fence with a backing board.

Routing using a table saw crosscut fence with a backing board. Aesthetically pleasing, nicely rounded edges.

Aesthetically pleasing, nicely rounded edges. Initial finish sanding with a sander

Initial finish sanding with a sander Wetting down the board.

Wetting down the board. Finer sanding with a block.

Finer sanding with a block. After a couple coats of mineral oil.

After a couple coats of mineral oil. Applying the final coat.

Applying the final coat. Rough-sawn lumber

Rough-sawn lumber Lindsay’s cutting board.

Lindsay’s cutting board. Gentlemen, start your engines!

Gentlemen, start your engines! Lise kayaking. Joanna Mitchell picture.

Lise kayaking. Joanna Mitchell picture. Lise and Joanna kayaking.

Lise and Joanna kayaking. Drinking wine from a water glass, contemplating buying an antique tractor. Joanna Mitchell picture.

Drinking wine from a water glass, contemplating buying an antique tractor. Joanna Mitchell picture. At Bell Falls. Joanna Mitchell picture.

At Bell Falls. Joanna Mitchell picture. Red-breasted nuthatch.

Red-breasted nuthatch.

The aptly named Canada Darner.

The aptly named Canada Darner. Bell Falls.

Bell Falls. Wetland near Limberlost.

Wetland near Limberlost.

Curly, spiraling seed heads. OK, I liked these guys.

Curly, spiraling seed heads. OK, I liked these guys. Smartweed.

Smartweed.

Ripping boards into strips.

Ripping boards into strips. Gluing jig.

Gluing jig.

Dried glue that needs to cleaned off.

Dried glue that needs to cleaned off.

Center piece flipped over.

Center piece flipped over. Cutting a slot.

Cutting a slot.

Gluing the pieces together.

Gluing the pieces together. The center of the cutting board, approximately 22 inches long and 6 inches wide. More to come.

The center of the cutting board, approximately 22 inches long and 6 inches wide. More to come. Pte. Moo, downstream from the Fermi nuclear plant.

Pte. Moo, downstream from the Fermi nuclear plant. Full length board showing warp.

Full length board showing warp. Full length board on the saw. The long blue hose connects to a shop vac.

Full length board on the saw. The long blue hose connects to a shop vac. Cutting the boards. Notice the appropriate safety gear.

Cutting the boards. Notice the appropriate safety gear. The end result, a pile of rough finished boards ready for the next step.

The end result, a pile of rough finished boards ready for the next step.

Sled with two wedged up boards. My sled is 1.5 inch MDF. It gets pretty heavy when loaded with a dense wood like bloodwood.

Sled with two wedged up boards. My sled is 1.5 inch MDF. It gets pretty heavy when loaded with a dense wood like bloodwood. Sled on the planer.

Sled on the planer. Sled coming through the planer.

Sled coming through the planer.

Smoothing on successive passes.

Smoothing on successive passes. Finished smooth boards.

Finished smooth boards. Smooth board and rough board for comparison.

Smooth board and rough board for comparison. Planning the second side of the boards.

Planning the second side of the boards. Board clamped into jig.

Board clamped into jig. Running the board and jig through the table saw to produce a clean edge, square to the surface. That spinning blade is not something to be trifled with. A mistake here can make counting to five on one hand difficult if not impossible.

Running the board and jig through the table saw to produce a clean edge, square to the surface. That spinning blade is not something to be trifled with. A mistake here can make counting to five on one hand difficult if not impossible. Finished board. Two flat parallel sides and a smooth edge square to the sides for a cutting reference.

Finished board. Two flat parallel sides and a smooth edge square to the sides for a cutting reference. Comparison of finished board and an unprocessed board.

Comparison of finished board and an unprocessed board.![IMAG0056[1]](https://biggishyears.com/wp-content/uploads/2018/08/imag00561.jpg?w=660) Lindsay helping pack.

Lindsay helping pack.![IMAG0057[1]](https://biggishyears.com/wp-content/uploads/2018/08/imag00571.jpg?w=660) Loaded and ready to roll.

Loaded and ready to roll.

What they got to see (NASA photo).

What they got to see (NASA photo).![IMAG0065[1]](https://biggishyears.com/wp-content/uploads/2018/08/imag00651.jpg?w=660) What I stared at all day.

What I stared at all day.![IMAG0062[1]](https://biggishyears.com/wp-content/uploads/2018/08/imag00621.jpg?w=660) This was a little scary. Guess they ave to learn somewhere.

This was a little scary. Guess they ave to learn somewhere. Female common green darner.

Female common green darner. Violet dancer.

Violet dancer. Calico pennant.

Calico pennant. One of the meadowhawks, probably red-faced.

One of the meadowhawks, probably red-faced.

Philly skyscrapers.

Philly skyscrapers.

The graves of Revolutionary War soldiers and sailors.

The graves of Revolutionary War soldiers and sailors.

Geno’s and Pat’s Philly steak sandwiches, also know as heart attacks on a bun.

Geno’s and Pat’s Philly steak sandwiches, also know as heart attacks on a bun. The open-air Italian Market of South 9th street.

The open-air Italian Market of South 9th street. If you want really fresh chicken.

If you want really fresh chicken.